testing of hardness and impact strength|brinell hardness testing : manufacturing Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality . webTuning XJ6. Nesse jogo inspirado na Yamaha XJ6 (XJ6N e XJ6F), você pode modificar as peças originais da moto. Troque rodas, escapamento, retrovisores, setas, etc. Ao final, é .

{plog:ftitle_list}

Confira a agenda dos jogos de hoje e todos os jogos no Brasil e ao redor do mundo. Acesse ge.globo.

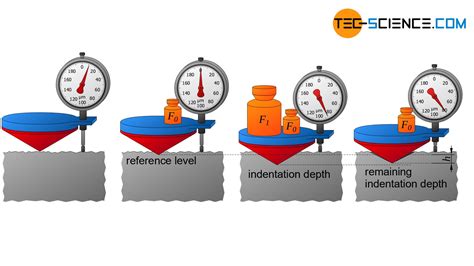

The impact hardness test methodology is described in Figure 1. An indenter retraction distance of 6μm and a step force of 6mN was used to create the impact experiment. The key parameters .The results of such tests are used for two primary purposes: 1) engineering design (for example, failure theories based on strength, or deflections based on elastic constants and component .

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality .It is for these reasons that testing of hardness is so important part of impact strength in engineering and mechanics. The following article includes information on testing of hardness, .

The ductility and strength (measured by a tensile test), related hardness properties and fracture toughness (or impact resistance) are the three most frequently required materials properties. An impact test is used to determine a material’s impact strength, or the material’s ability to resist deformation when subjected to a sudden shock or impulse load. Learn more about it here.

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most . Where: R eH is the upper yield strength; R m is the tensile strength; H RB is Rockwell hardness.. 2.1.2 Relative deviation analysis of conversion results. Based on the fitted quadratic regression model, the .

Impact test. Many materials, sensitive to the presence of flaws, cracks, and notches, fail suddenly under impact. The most common impact tests (Charpy and Izod) employ a swinging pendulum to strike a notched bar; heights before and after impact are used to compute the energy required to fracture the bar and, consequently, the bar’s impact strength. In the Charpy test, the test .

In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as . Hardness testing may be useful for monitoring processes. As long as the hardness stays consistent, the process is probably within specification as well. On the negative side: Hardness correlates only very loosely to yield strength and ductility, with high scatter (Figure 1). Hardness testing has many pitfalls that can lead to inaccurate .Using test methods such as scanning electron microscopy, hole-drilling strain-gage method, semiautomatic and automatic image analysis, and X-ray diffraction, parameters like elastic moduli, impact strength, ductility, hardness, residual stress, and grain size are measured.A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

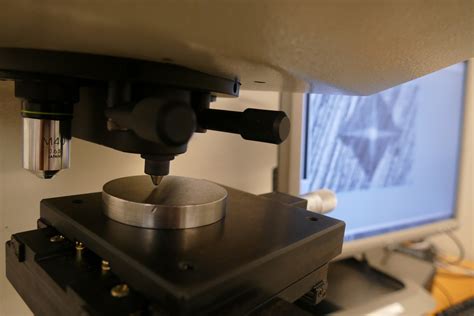

3.2 Hardness Testing. Hardness testing in this study using the Future Tech Rockwell Hardness Tester Series (LC 200 RB testing) refers to the ASTM E18 test standard. Hardness testing is used to measure a material’s hardness; it is also a significant aspect of assessing the material’s mechanical properties. Hardness testing can be done in .

q-pert

rockwell hardness testing limits

Learn how toughness differs from hardness and strength, and find plastics exhibiting a suited range of toughness for your specific needs. The material selection platform . The impact test is the ability of a material to absorb energy during plastic deformation. It signifies toughness or impact strength of a material.Hardness testing to Brinell is mainly performed with HBW 1/30 or HBW 2.5/187.5. For hardness testing to Rockwell, scale B (HRB) is used for fasteners of property class 4.6 - 6.8 and scale C (HRC) for property classes 8.8 - 12.9. In the event of arbitration, the Vickers hardness test shall be used as reference.

Conversely, impact toughness tests (such as the CVN impact test) are cheaper and easier to conduct. . it has been well known that the goal of achieving high strength (hardness) and high toughness at the same time goes generally into conflict (Ref 75), mainly because a higher hardness the material has lower plastic deformation available to the . The ductility and strength (measured by a tensile test), related hardness properties and fracture toughness (or impact resistance) are the three most frequently required materials properties. 2. IZOD Test. The ASTM impact energy is measured in J/m or ft-lb/in. Impact strength results from dividing the value for impact energy in (J or ft-lb) by the notch thickness (mm or inches) of the specimen, for an average of 5 test cycles.

The hardness is not an intrinsic property but reflects the hardening state in CG. The ratio of hardness to strength can also be reflected by indentation morphology. The ratio of hardness to strength increases with increasing parameter α. H V = 3σ UTS is valid for materials with relatively high strength and better toughness.

well as tension, hardness, torsion, and impact tests in particular. Mechanical Testing Mechanical tests (as opposed to physical, electrical, or other types of tests) often involves the deformation or breakage of samples of material (called test specimens or test pieces). Some common forms of test specimens and loading situations are shown in .TCR has a comprehensive range of Mechanical Testing services with a dedicated in-house machine shop that assists in sample preparation. Test specimens are duly prepared for metallic and non-metallic materials for the . IZOD test is vertical while Charpy tests are horizontal but both measure impact resistance. The main difference lies within a notch sample orientation during testing where in an Izod notched bar impact test, the specimen stands vertically with its notch facing towards the pendulum whereas, during charpy v-notch impact test ,the samples are placed horizontally .

There are several common mechanical properties that are tested, including elastic modulus, shear modulus, yield strength, ductility, and hardness. Each of these properties is tested using different methods and techniques. .Charpy Impact Testing is essentially a stress test for materials. While lifting weights helps us gauge our physical strength, this testing method serves as an indicator of the ability of metals and other materials to withstand sudden impact or shock. Imagine you have two different types of metal, one for building bridges and another for making .

The strength or hardness of a material is a function of composition, processing, temperature, and strain rate. . The impact hardness test methodology is described in Figure 1. An indenter retraction distance of 6µm and a step force of 6mN was used to create the impact experiment. The key parameters

Eltek Labs can test a variety of properties such as tensile strength, flexural strength, impact strength, density, hardness, water absorption, and more. ELTEK International Laboratories 636-949-5835 / Request a Quote IZOD Impact Strength Test: Izod impact testing is an ASTM impact standard testing method that can test materials to a ¼ size. It involves using a raised pivoting arm to hit and break material. . Hardness Testing. Hardness testing allows manufacturers to know the hardness of a material, i.e., the ability of the material to resist indentation .

rockwell hardness testing

If you’re looking for the mechanical (or thermal or electrical) property data of a given material, you can get it from the American Society for Testing Materials (ASTM) or by consulting the material manufacturer’s website. Typically, the data values available range from material stiffness and mechanical strength to hardness and tensile . Our discussion will cover the different types of impact testing, the necessary equipment, and the valuable data these tests provide. Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for determining a material’s ductile-to-brittle transition temperature and its ability to resist deformation due to impact loads.What Is Hardness Testing? Hardness testing assesses a material’s ability to resist permanent deformation at its surface by applying pressure with a harder material. It finds applications across various industries for comparing and selecting materials, as well as ensuring quality control in manufacturing or hardening processes.

1. rockwell hardness test 10 2. vickers hardness test 13 3. impact test 16 4. tensile test 21 5. compression test 26 6. shear strength test 29 7. heat treatment 32 8. wear test 35 9. microstructure 39 10. brinell hardness test 43 11. torsion test 46 12. fatigue test 49 13. bending test 53 14. ultrasonic test 56 15. magnetic particle test 58 Impact test specimen types include notch configurations such as V-notch, U-notch, and keyhole notch. . The impact strength is determined by the loss of energy of the pendulum as determined by precisely measuring the loss of . The Rockwell hardness test is the most frequently used hardness testing method and is considered to be more accurate . The most common types of mechanical testing include tensile testing, compression testing, hardness testing, impact testing, fatigue testing, and torsion testing. These tests provide important information about a material’s strength, ductility, toughness, and other properties, which are critical in determining its suitability for specific .

q-pert assay

WEB5 de jun. de 2020 · El Presidente: Created by Armando Bo. With Andrés Parra, Karla Souza, Paulina Gaitan, Alberto Ajaka. The head of a small .

testing of hardness and impact strength|brinell hardness testing